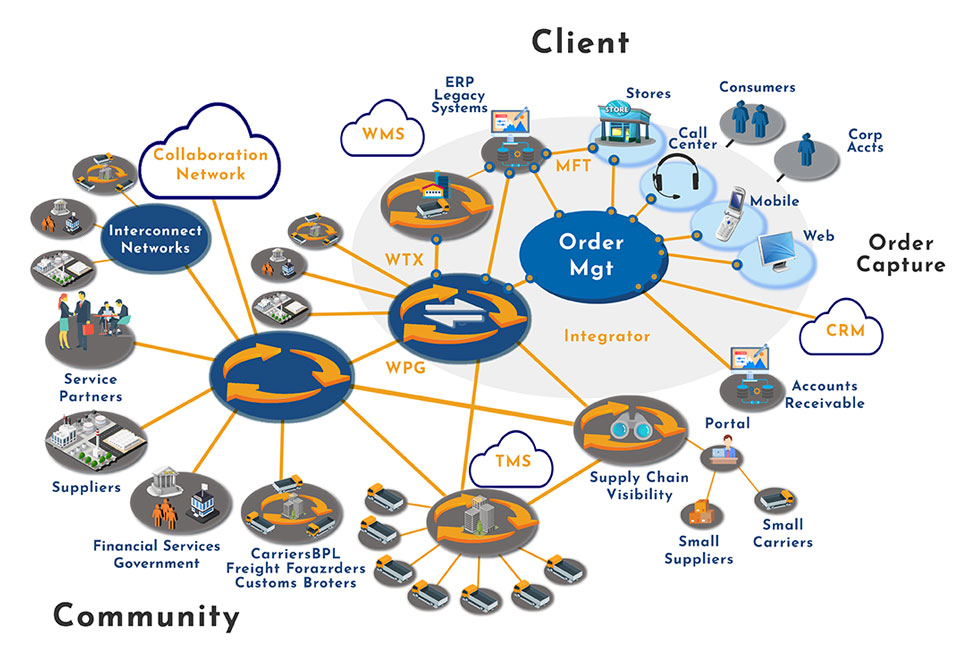

Supply chains have been digitally transforming for years, the COVID-19 pandemic has put global supply chain networks under intense scrutiny, highlighted their weaknesses and flaws, and forced logistics providers to accelerate digital transformation efforts. Supply chain leaders must balance resilience with cost efficiency and prepare their networks for continuing disruptions

Valenta helps logistics organisations thrive in today’s fast-paced, competitive market with automation technologies such as robotic process automation (RPA), intelligent process automation (RPA + AI) and conversational AI.

By effectively implementing these and other cutting-edge solutions, Valenta enables logistics clients to effectively navigate the complexities of import/export operations and compliance, freight forwarding, shipping and receiving, warehousing, inventory management, transportation management and back-office functions conversational AI.